Need help with your air compressor pressure switch? Well, you’re in the right place! Whether it’s troubleshooting issues or understanding how to adjust the settings for optimal performance, we’ve got you covered. The air compressor pressure switch plays a crucial role in regulating the air pressure and ensuring smooth operation of your equipment. Let’s dive in and explore everything you need to know about this essential component. Let’s get started!

Air Compressor Pressure Switch: Everything You Need to Know

Air compressors are essential tools in many industries and can also be found in workshops and garages for personal use. The pressure switch on an air compressor plays a crucial role in regulating the compressor’s operation. In this comprehensive guide, we will delve into the workings of an air compressor pressure switch, its importance, common issues, troubleshooting tips, and maintenance practices.

What is an Air Compressor Pressure Switch?

An air compressor pressure switch is a device that controls when the compressor should start and stop building up air pressure. It monitors the pressure in the compressor tank and acts as a safety mechanism to prevent over-pressurization.

How Does an Air Compressor Pressure Switch Work?

When the pressure in the tank drops below a set level, the pressure switch activates the compressor to start building pressure. Once the pressure reaches the upper limit, the switch signals the compressor to stop. This cycle repeats as needed to maintain a consistent air pressure level.

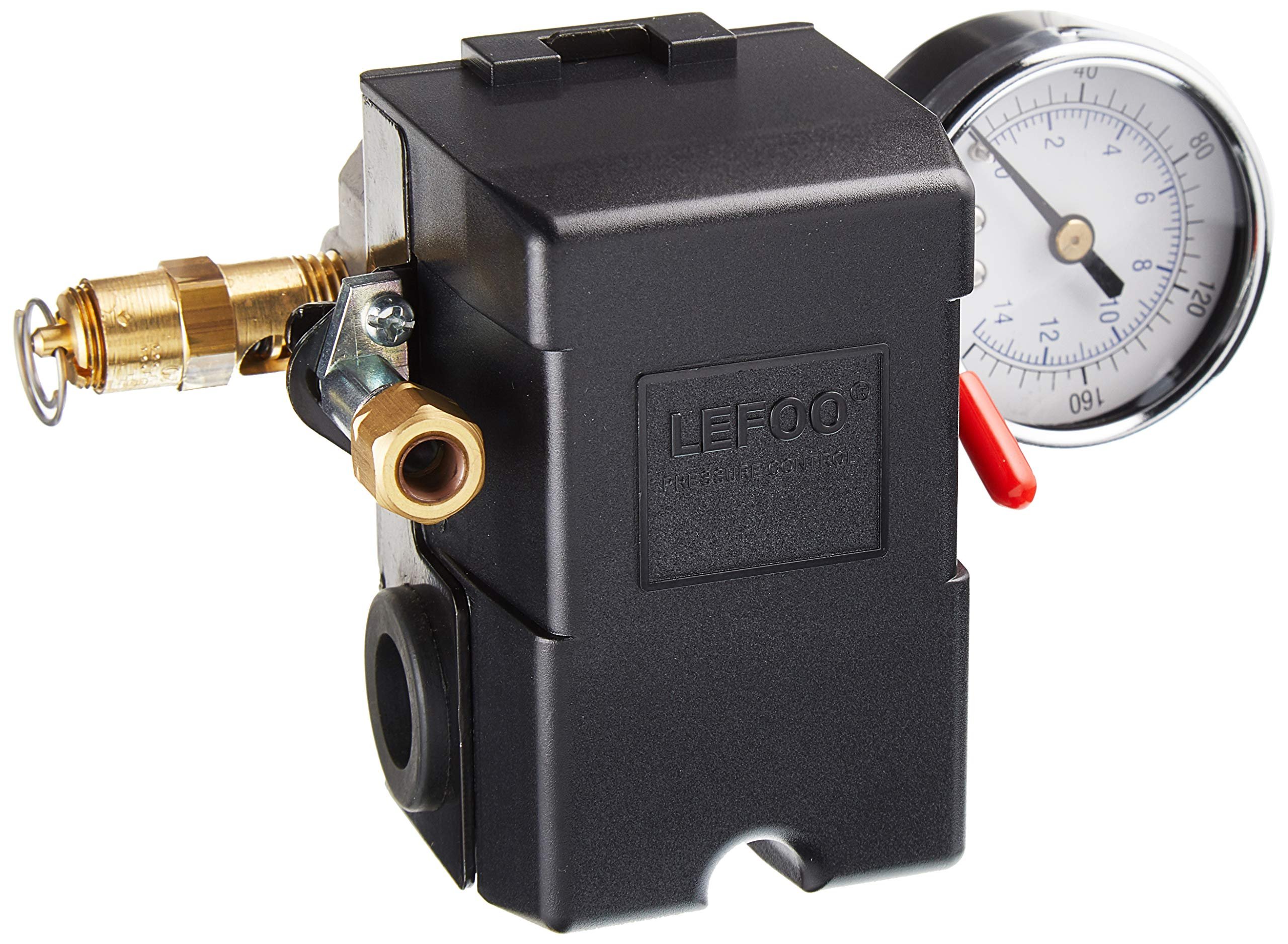

Components of an Air Compressor Pressure Switch

The pressure switch comprises several key components that work together to regulate the compressor’s operation:

- Pressure Sensing Element: Monitors the air pressure in the tank.

- Electrical Contacts: Control the flow of electricity to the motor based on pressure levels.

- Adjustment Mechanism: Allows users to set the desired pressure range.

- Pressure Release Valve: Releases excess pressure to prevent damage.

Importance of the Air Compressor Pressure Switch

The pressure switch is crucial for the safe and efficient operation of an air compressor. Here’s why it’s important:

- Prevents over-pressurization, which can lead to equipment damage or injury.

- Regulates the compressor’s duty cycle, optimizing its performance and energy efficiency.

- Ensures consistent air pressure for various tools and equipment connected to the compressor.

Common Issues with Air Compressor Pressure Switches

While air compressor pressure switches are designed to be reliable, they can experience issues over time. Some common problems include:

- Failure to turn on or off at the set pressure levels.

- Inaccurate pressure readings leading to improper operation.

- Air leaks around the pressure switch assembly.

- Corrosion or damage to electrical contacts affecting performance.

Troubleshooting Air Compressor Pressure Switch Problems

If you encounter issues with your air compressor pressure switch, here are some troubleshooting tips to help identify and resolve the problems:

- Check for loose electrical connections and tighten them if necessary.

- Clean the pressure sensing element to ensure accurate pressure readings.

- Inspect the adjustment mechanism and recalibrate it if needed.

- Replace damaged or worn-out components, such as electrical contacts or seals.

Maintenance Tips for Air Compressor Pressure Switches

Proper maintenance is key to ensuring the longevity and performance of your air compressor pressure switch. Here are some maintenance tips to follow:

- Regularly inspect the pressure switch for signs of wear or damage.

- Clean and lubricate moving parts to prevent friction and corrosion.

- Test the pressure switch’s operation periodically to ensure it functions correctly.

- Replace any worn-out components or seals to prevent air leaks.

By following these maintenance practices, you can extend the lifespan of your air compressor pressure switch and ensure smooth operation.

In conclusion, the air compressor pressure switch is a vital component that helps regulate air pressure, protect the compressor from damage, and optimize its performance. Understanding how the pressure switch works, knowing common issues, troubleshooting problems, and performing regular maintenance are essential for maximizing the efficiency and lifespan of your air compressor. By taking care of this critical component, you can ensure reliable operation and safe use of your air compressor for years to come.

Air Compressor Repair – pressure switch, unloader, and check valve

Frequently Asked Questions

What is the role of an air compressor pressure switch?

An air compressor pressure switch plays a crucial role in regulating the pressure levels within the compressor system. It is responsible for monitoring the tank pressure and initiating the motor to start or stop based on pre-set limits.

How do I know if my air compressor pressure switch is faulty?

Signs of a faulty air compressor pressure switch include irregular cycling of the compressor, inconsistent pressure levels, or the compressor not turning on/off at the set thresholds. Additionally, visible damage or burning smell near the switch could indicate a problem.

Can I adjust the pressure settings on my air compressor pressure switch?

Yes, most air compressor pressure switches come with adjustable pressure settings. By referring to the manufacturer’s guidelines, you can typically adjust the cut-in and cut-out pressure levels to suit your specific requirements.

What maintenance tasks should be performed on an air compressor pressure switch?

Regular maintenance tasks for an air compressor pressure switch include checking for leaks, ensuring electrical connections are secure, keeping the switch clean from debris, and testing pressure levels periodically to ensure optimal functionality.

Are air compressor pressure switches universal or do I need a specific one for my compressor model?

Air compressor pressure switches vary in terms of compatibility with different compressor models. It is essential to check the specifications provided by the manufacturer to ensure you get a switch that is compatible with your specific air compressor model.

Final Thoughts

In conclusion, understanding the air compressor pressure switch is crucial for maintaining optimal performance and safety. Regularly monitoring and adjusting the pressure settings can prevent damage and enhance efficiency. Proper maintenance of the switch can extend the lifespan of your air compressor and prevent costly repairs. Always refer to the manufacturer’s guidelines for specific instructions on handling the air compressor pressure switch. Remember, a well-functioning pressure switch is essential for the smooth operation of your air compressor.